- Author:MQH

- 2022-11-25 17:25

- Published in Jiangsu

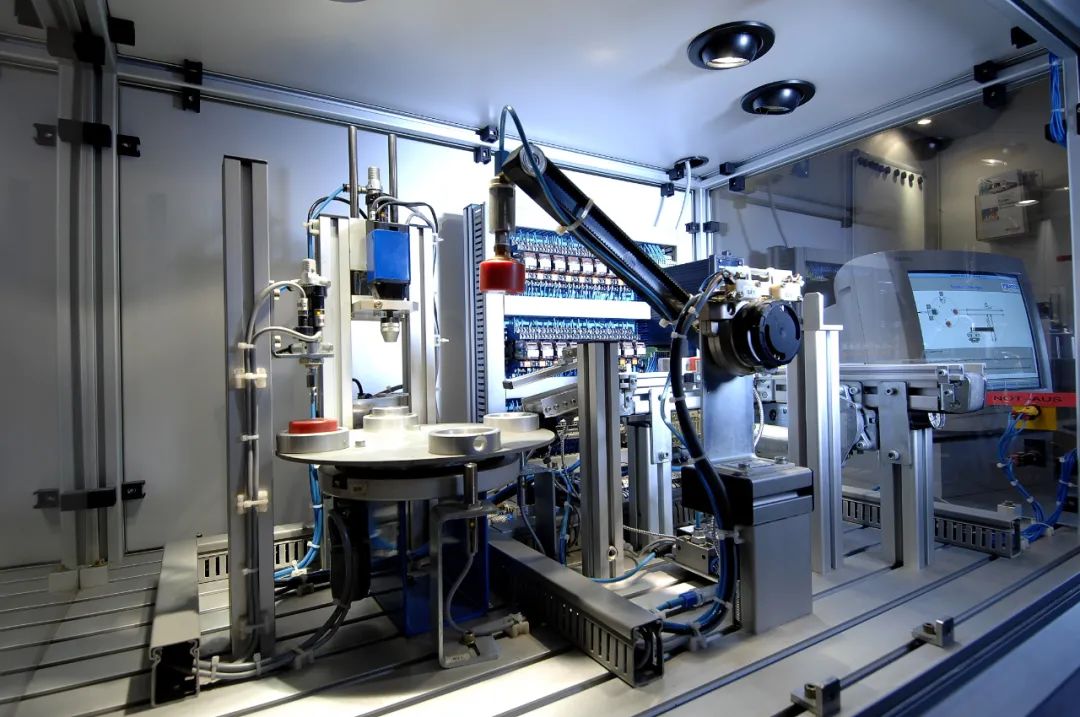

The significance of automated production

In recent years, with the development of Chinese society, the labor advantage of China's manufacturing industry has been slowly disappearing. In the current era, the manufacturing industry is also undergoing automation transformation. Enterprises only continue to explore new technologies, for large-scale manufacturing production, want to improve the competitiveness of enterprises in the world, improve productivity only rely on technology to improve, the introduction of automation, intelligent technology. In this way, an automated production line integrating the above technologies came into being, and the following Xiaobian will share with you the importance of four automated production lines for production enterprises.

1、Industrial manufacturing automation technology can greatly improve production efficiency, shorten product production cycle, and provide a time guarantee for products to seize the market. Automated production lines not only improve the working conditions, reduce the labor intensity of workers, but also to ensure production safety, improve labor productivity and product quality, while reducing the loss of energy and raw materials, save auxiliary processing time, and ultimately reduce product manufacturing costs.

2、When the automatic production line is realized in the enterprise, the production process of all or part of the processing of the product is completed by mechanical equipment, instruments and automation devices, and humans can be freed from heavy labor. Human functions can be in system design, assembly, adjustment, inspection, supervision of the production process, quality control, and adjustment and overhaul of automation equipment and devices, without the need for direct human involvement in the operation.

3、Machinery manufacturing automation technology can improve production efficiency, reduce the consumption and use of labor, so as to help enterprises reduce production costs, improve the economic benefits of enterprises; The extensive use of various types of robots in the production process has improved the automation, intelligence and industrialization of industrial production, and promoted the development of science and technology to a higher level.

4、Mechanical manufacturing automation technology adopts standardized production, which can reduce and reduce raw material consumption caused by human uncertainty factor in the production process and reduce waste generation, which is conducive to the realization of energy conservation and emission reduction goals of the state.

Advantages of automated production

Manufacturing automation is not only replacing human physical and mental labor, but also showing many advantages:

1、Highly automated program without manual operation; Reduce the consumption and use of labor, so as to help enterprises reduce production costs and improve the economic benefits of enterprises

2、High working efficiency, improve the production efficiency of enterprises; Short product production cycle provides time guarantee for products to seize the market;

3、The production process of the whole process is stable, improve the consistency of the product;

4、Suitable for mass production, reducing the production cost of enterprises.

5、You can perform tests that are difficult or impossible to perform manually. For example, for testing with a large number of users, it is not possible to have enough testers at the same time, but it is possible to achieve the purpose of testing by simulating many users at the same time through automated testing.

6、Make better use of resources. Automating tedious tasks can improve accuracy and tester motivation, freeing up test technicians to devote more energy to design. Some tests are not suitable for automated testing, but only for manual testing. Automating tests that can be automated allows testers to focus on the manual part of the test, improving the efficiency of manual testing.

Therefore, with the progress of society, industrial production automation will replace cheap labor force to a great extent, improve the level of social productivity, improve the international competitiveness of our manufacturing industry.

The difficulty of realizing automated production

The difficulty of manufacturing automation is the feasibility evaluation and verification. In terms of the feasibility of implementation, whether the product is suitable for automated manufacturing, as well as what drawbacks and risk points of automation should be fully considered. Secondly, in the verification stage of the implementation of product production automation, the verification adequacy and feasibility of each step need to be verified comprehensively in order to ensure the stability of subsequent batch automated production.

Precautions for automated production

Production automation has its advantages and disadvantages, and the following issues need to be noted when considering automation:

The automation should follow the relatively simple mode of operation steps;

The automation should have reasonable fault tolerance rate to ensure the stability of its operation;

The premise of automation is to be able to match its corresponding capacity;

The implementation of automation needs to consider its operational safety;

All verification results of automation are required to ensure the stability and quality of product manufacturing.

The importance and necessity of industrial automation With the progress of The Times, our industry has entered the era of automation and the era of information. If we want to make use of our information technology, we must first solve the problem of our industrial automation, and use a variety of automated industrial production equipment in our industrial production to monitor our industrial production to provide accurate data for our information technology, so that our production equipment can produce the best products. Therefore, the realization of automated production of our products, on the one hand, can improve production efficiency, as well as the stability of product quality, on the other hand, can also achieve industrial upgrading, improve the competitive advantage of products.

中文

中文 Feat

Feat

Consult

Consult Help

Help