- Author:MQH

- 2022-11-18 17:00

- Published in Jiangsu

Tools are usually divided into turning tools, hole processing tools, milling tools, broaching tools, thread tools, gear tools, automatic lines and CNC machine tools and other types of tools.

Process analysis of plastic products

Before the mold design, the designer should fully study whether its plastic products meet the processing principle of injection molding, and it is necessary to reach a consensus after careful consultation with the designer of the product. This includes the necessary discussion of the geometric shape, dimensional accuracy and appearance requirements of the product to avoid unnecessary complexity in the subsequent mold manufacturing.

die structure design

A set of high-quality molds, in addition to the need for good processing equipment and skilled mold manufacturing technology, but also need another very important factor: mold design! Especially for complex molds, the quality of the mold design is the main factor determining the quality of the mold. Under the premise of an excellent mold design to meet the requirements of customers, it can also reduce the processing cost, processing difficulty and processing time.

To do this, it is not only necessary to fully digest the requirements of the guests, but also to fully understand the injection molding machine, mold structure, processing technology and the processing capacity of the mold factory itself. Therefore, to improve the level of mold design needs to do the following points:

1、Figure out every detail in each mold design and understand the purpose of all parts in the mold.

2、In the design more reference to the previous similar design, and understand its situation in mold processing and product production, learn from the experience and lessons.

3、Observe the working process of the injection molding machine to deepen the understanding of the mold and the injection molding machine.

4、You can go to the factory to understand the processing process and understand the characteristics and limitations of each process.

5、Understand the mold test results and mold modification of their own design, learn lessons.

6、In the design, try to use the mold structure that was more successful before.

7、Learn more about the influence of mold into water on products.

8、Study some special mold structures and learn the latest mold technology.

Determine mold materials and select standard parts

When choosing mold materials, it is necessary to consider the accuracy and quality of the product, but also to combine the processing and heat treatment of the mold factory to actually operate, and then make the right choice. In addition, in order to shorten the manufacturing cycle, the existing standard parts can be fully utilized.

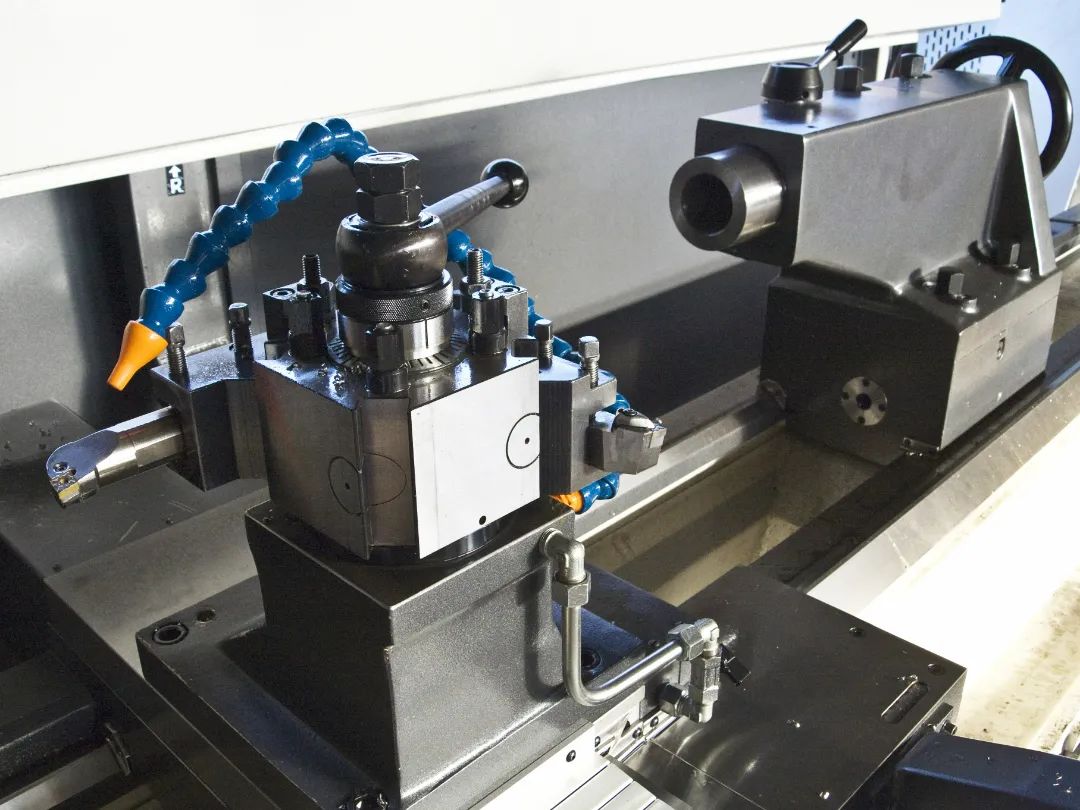

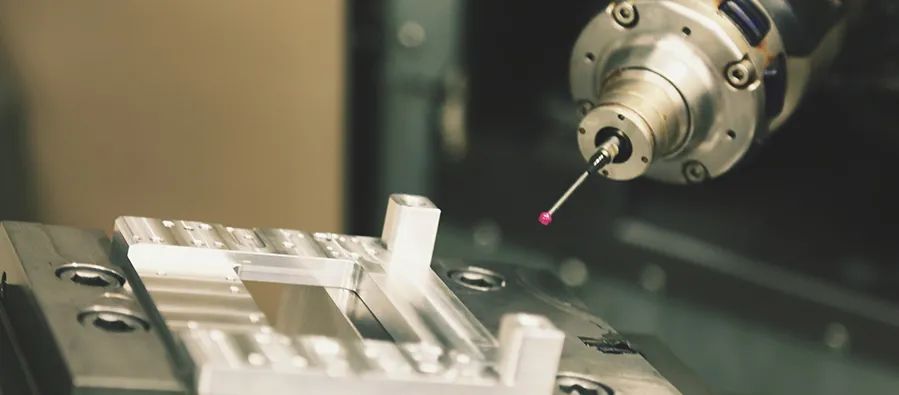

Parts processing and mold assembly

In addition to the accuracy of the mold in the design to give the best structure and reasonable tolerance, parts processing and mold assembly is also very important. Therefore, in the selection of processing accuracy and processing methods, it is the leading position in mold manufacturing.

The size error of the molded product is mainly:

1、The manufacturing error of the mold is about 1/3.

2、The error caused by mold wear is about 1/6.

3、The error caused by uneven shrinkage of molded parts is about 1/3.

Total error =(1)+(2)+(3)+(4)

Therefore, in order to reduce the error of mold manufacturing, the processing accuracy should first be improved, and with the use of CNC machine tools, this problem has been well controlled. In addition, in order to prevent the error caused by mold wear and deformation, the key parts such as the cavity and core can be quenched when the processing precision is higher and the output is larger. In the medium and large molds, in order to save materials and facilitate processing, the Mosaic structure can be used in the mold design.

In order to solve the error caused by the uneven shrinkage of the molded part and the inconsistency between the predetermined contraction and the actual contraction, 1/3 of the product tolerance is generally selected as the manufacturing tolerance of the mold during mold manufacturing, which is to leave a large adjustment room for the later molding process and facilitate the later resolution of the error caused by the molding process.

Test moulds

A set of molds from the beginning of design to assembly, but only 70% to 80% of the entire manufacturing process has been completed. For the error caused by the inconsistency between the predetermined shrinkage and the actual shrinkage, whether the demoulding is smooth or not, how the cooling effect is, and the influence of the size, position and shape of the gate on the accuracy and appearance of the product, it is necessary to test the test mold.

Therefore, mold testing is the last indispensable step in determining whether the mold is qualified and selecting the best forming process.

中文

中文 Feat

Feat

Consult

Consult Help

Help