- Author:MQH

- 2022-11-25 17:25

- Published in Jiangsu

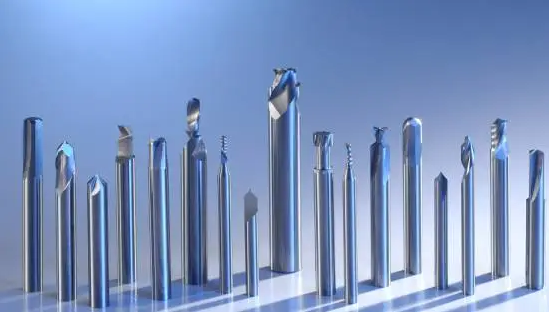

Tool knowledge sharing

Tools are usually divided into turning tools, hole processing tools, milling tools, broaching tools, thread tools, gear tools, automatic lines and CNC machine tools and other types of tools.

Tools can also be divided into other materials: high-speed steel tools, cemented carbide tools, ceramic tools, cubic boron nitride (CBN) tools and diamond tools; According to the structure, it can be divided into integral tool, insert tool, machine clip tool and compound tool. Or according to whether it is standardized into standard tools and non-standard tools.

Tool selection is one of the important contents in CNC machining technology, which not only affects the machining efficiency of machine tools, but also directly affects the machining quality of parts.

01 Introduction to common tools

Turning tool is one of the most widely used tools in metal cutting. It can be used on the lathe to process the outer circle, end plane, thread, inner hole, and can also be used for grooving and cutting. The turning tool can be divided into integral turning tool, welding assembly turning tool and mechanically clamped blade turning tool in structure.

Turning tools with mechanically clamped blades can be divided into machine tool turning tools and indexable turning tools. The cutting performance of mechanically clamped turning tool is stable, and workers do not have to sharpen the tool, so it is used more and more in modern production.

02 The characteristics of CNC machine tools

1、With good stable cutting performance, the tool has good rigidity, high precision, and can carry out high-speed cutting and strong cutting.

2、A large number of tools are made of cemented carbide materials or high-performance materials (such as ceramic blades, cubic boron nitride blades, diamond composite blades and coated blades, etc., and more high-speed steel tools are high cobalt, high vanadium, aluminum-containing high-performance high-speed steel and powder metallurgy high-speed steel).

3、The tool (blade) has good interchangeability and can be quickly changed. The tool can be automatically and quickly changed to shorten the auxiliary time.

4、The tool is suitable for the processing of high-precision workpieces, especially when the indexable blade is used, because the tool body and the blade repeated positioning accuracy is high, so good processing quality can be obtained.

5、The tool has reliable chip rolling and chip breaking performance. The use of CNC machine tools can not be stopped at will to deal with chips, and the long chip appearing in the processing will affect the safety of the operator and the processing efficiency.

6、The tool has the function of adjusting the size. The tool can be pre-adjusted (to the tool) or compensated in the machine to reduce the adjustment time of the tool change.

7、Tool serialization, standardization and modularization Tool serialization, standardization and modularization are conducive to programming, tool management and cost reduction.

8、Multi-functional combination and specialization.

03 CNC machining tool requirements

Stable and reliable cutting performance, high durability, reliable rolling, chip breaking and chip removal capabilities, high processing accuracy and repeated positioning accuracy, can achieve tool size pre-adjustment, quick tool change and automatic tool change.

04 Tool structure

1、Integral: The tool is one body, made of a blank material, not separate.

2、Welding type: Using welding method to connect, tool rod.

3、Clamping type: clamping type is divided into two types: non-indexable and indexable; Usually the CNC tool adopts the machine clamp type.

4、Special types: such as compound cutting tools, shock absorbing cutting tools.

05 Tool material

1、High Speed Steel Tool Bit

2、Carbide-tipped tool

3、Oxide-ceramic cutting tool

4、Extra high pressure sintered tool

06 Tool processing mode

1、Turning tools: outer circle, inner circle, thread, grooving, cutting tools, etc.

2、Drilling tools; Including drill, tap, reamer, etc.

3、Boring tool.

4、Milling tool; Including face milling cutter, end milling cutter, three side edge milling cutter, etc.

中文

中文 Feat

Feat

Consult

Consult Help

Help