- Author:MQH

- 2023-03-10 17:00

- Published in Jiangsu

At the first session of the 14th National People's Congress that was being held recently, President Xi Jinping sighed after listening to the new report card reported by Deputy Shan Zenghai of the Jiangsu delegation:

“China's manufacturing industry category is very complete, now to work hard, is to improve comprehensively, the past low-end to go up, the layout of high-end. High-quality development should be reflected here. China cannot lack manufacturing at any time.”

In recent years, the labor advantage that China's manufacturing industry has long relied on is gradually disappearing. The cheap labor force, once the main driver of China's manufacturing industry, is not as large and cheap as it used to be, and companies are facing worsening labor shortages.

The manufacturing plant is a very technology-intensive place, from CAD, CAM to various machining technologies, CNC, EDM, wire cutting also includes measurement technology, but also contains all the forming technology. Therefore, for large-scale manufacturing and enterprises that want to compete globally, the only way to improve productivity is to rely on technology upgrading, the introduction of automation and intelligent technology. Automation is also the only way to develop mold factories. How can mold factories automate production?

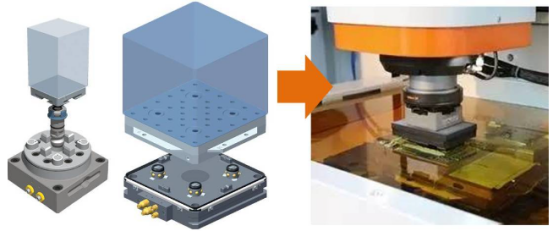

▌ Automation Level 1: Positioning jig with quick clamping

The use of quick-set positioning fixtures is the first step towards automation in the factory. The use of a unified fixture benchmark in different machine tools and processes, so that the workpiece and electrode replacement no longer need manual punching, a few seconds to achieve the replacement, repeated positioning up to 2μm of high precision.

▌ Automation Level 2: The machine integrates an automatic switching device

On the basis of the use of quick clamping and positioning fixtures, the machine tool is equipped with an automatic replacement of electrodes and workpieces, so as to achieve a longer automatic processing. However, the automatic processing capability of this automatic switching device is very limited.

▌ Automation Level 3: Configuration of the workpiece/electrode composite system

By configuring the workpiece/electrode composite system, a greater number of workpiece/electrode changes can be supported, a variety of different pallet systems can be handled, and central preset data and numerical control programs ensure high transparency in the machining process.

▌ Automation Level 4: Manufacturing unit

With one processing equipment, service multiple machine tools and equipment, through different machine tools and auxiliary equipment to achieve unattended processing, processing process with high transparency, real-time access to the workpiece and process information, through the coordinate measuring instrument to achieve online measurement, to ensure high quality production, to achieve unattended processing.

▌ Automation Level 5: Flexible manufacturing systems

With one processing equipment, service multiple machine tools and equipment, all machine tools and related information together, to achieve unified management of data flow and logistics, and the number of equipment can be extended according to demand, suitable for mass production. The number of devices can be extended according to demand.

For automation investments, customers often worry about compatibility between different devices! The most outstanding advantage of GF machining solutions is that it can provide customers with a true one-stop solution. From the provision of processing equipment, to the formulation of automation solutions, to the application of automation software, can meet the needs of customers.

中文

中文 Feat

Feat

Consult

Consult Help

Help