- Author:MQH

- 2023-03-24 17:00

- Published in Jiangsu

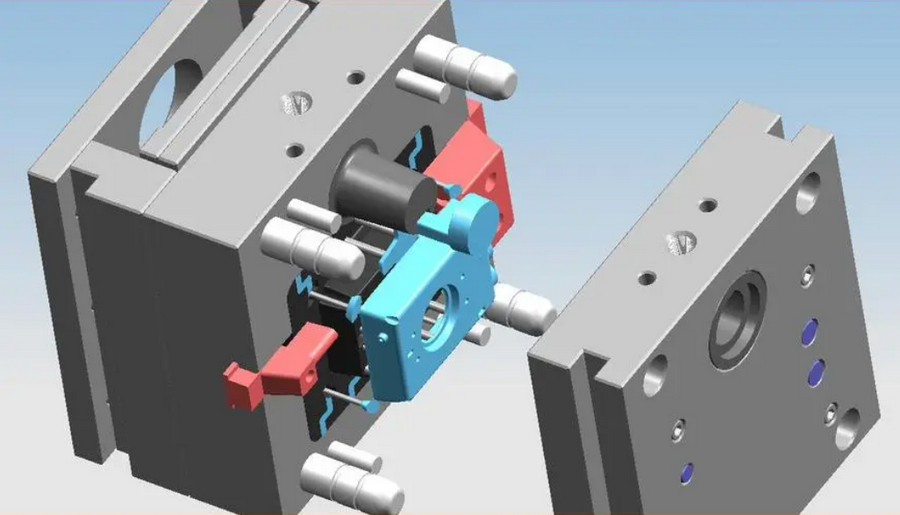

Mold is the basic process equipment of industrial production, in electronics, automobiles, motors, electrical appliances, meters, home appliances and communications and other products, 60% to 80% of the parts rely on mold forming, mold quality determines the level of product quality, therefore, mold is called "the mother of all industries." The mold is a "benefit amplifier", and the value of the final product produced by the mold is often dozens of times and hundreds of times the value of the mold itself.

Mold, an important supply equipment for modern industrial production, the development of modern industrial products and the improvement of the technical level, to a large extent depends on the development level of the mold industry, therefore, mold technology has become an important sign to measure the level of a country's manufacturing, it determines the international competitiveness of this country's manufacturing industry to a certain extent.

In recent years, the mold industry is not as good as before, fierce competition led to mold order prices down, some people choose to leave the industry. As a mold person who has struggled in the mold industry for more than ten years, I am deeply touched by the evolution of these years, and now I do some simple analysis, hoping to help everyone, especially those who have just engaged in or will engage in the mold industry.

First of all, mold is the mother of industry, mold can make the product reach mass production, improve efficiency, reduce costs, is impossible to be eliminated from the industry. Especially in the current era of rapid development of China's industrialization process, the mold industry is still a sunrise industry, still an industry full of opportunities!

The problem is that China's mold industry mainly processes low-to-mid-range molds, and high-end molds are not much. I believe that in the near future, the rise of China is unstoppable, and the turn of manufacturing is unstoppable, so is our mold industry naturally. After all, without first-class mold, it is impossible to make first-class products.

At the 14th National People's Congress held on March 5, 2023, General Secretary Xi Jinping clearly pointed out: China can not lack manufacturing at any time, at present, China's manufacturing categories and varieties are complete, the next step is to strive to develop high-end manufacturing and achieve comprehensive improvement. The state will vigorously support the development of high-end manufacturing.

The development of molds in the future mainly has such several development directions:

1.high precisionWhether the accuracy of the size can be achieved. The ones that used to do it best were Japan, Germany. With decades of continuous learning and innovation, our Chinese mold industry has also emerged a large number of companies specializing in high-precision mold manufacturing. To do high precision mold, the main elements are two, one is equipment, one is talent.

2.High efficiency means high automation.With the popularization of various automatic equipment for mold production and the improvement of the intelligence of standard parts inside the mold, the efficiency of mold production is getting higher and higher, and it will develop towards a higher and better realm. In this process, the requirements for mold designers will become higher and higher, at that time, mold designers can not only understand the automation equipment, but also participate in the design. In the future where the degree of visual mechanization is highly developed, the term general work will probably disappear. In the future, there are only three kinds of people: managers, technical people, and robots.

3.With the continuous development of new molds and technological innovation, many of the original mold rivers that need to be very complex and tortuous have become very simple.There are also many structures that were previously thought impossible that have become possible. These are new opportunities and challenges for the mold industry, specifically, opportunities and challenges for mold designers, and mold factories that have mastered these new mold design and manufacturing technologies will have more initiative. Mold, always rely on technology and quality of the industry ah!

4.The trend of product development and mold integration is also inevitable. This change is a change that affects the manufacturing model more than the assembly line replacing the all-around mold master. Simply put, it is the integration of mold design and product research and development into a new position, a new position that can be responsible for the entire product from the appearance to the organization, to the mold, to the mold processing, mold production, and product assembly. Become the absolute core of the manufacturing industry.

中文

中文 Feat

Feat

Consult

Consult Help

Help